Don's Guide to passing Tech Inspection

Don's Tech Guide

Note: Some of the wording might not be exactly the same as either the

IHRA or NHRA Official Rule Books and our recommendations may exceed some

of the basic requirements for your class as required by NHRA or IHRA.

Rollbar / Cage

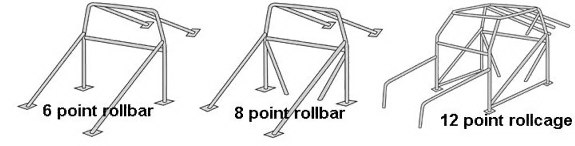

QUESTION: From our mailbox - Is a rollbar and a rollcage the same thing or is a rollbar just the hoop behind the driver?

ANSWER: A six or eight point rollbar is often described as a rollcage but in fact

only becomes a cage with the addition of the windshield and dash bars - see illustration below - for more info check the bar / cage rules lower on this page.

Rollcages can vary from a 10 point - similar to the 12 point above but without the forward struts - to some funny car type tube chassis cages with dozens of attachment points.

FLYWHEEL / SCATTERSHIELD

QUESTION: From our mailbox - I plan to put a 4 speed in my Street Class race car. Do I need a scattershield to pass tech?

ANSWER: Not for your class. Rulebook says: 11.49 & quicker - SFI 6.1 Flywheel shield and SFI 1.1 clutch, pressure plate and flywheel are mandatory.

|

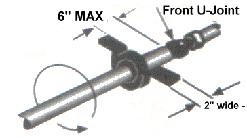

DRIVESHAFT LOOPS

QUESTION: From our mailbox - I have slicks on my car but it only goes 15 seconds for an ET. Do I need to have a driveshaft loop? What are the rules?

ANSWER: No Matter what the ET a loop is required if your car has slicks.

Rulebook says: 1/4"thick X 2"wide steel - must completely encircle the driveshaft

within 6 inches of the front U-joint and be attached to the floor with a minimum of

four 3/8" diameter bolts.

|

|

We have seen some pretty odd looking things under cars but this is where

the WORST are. Biggest problem: Inadequate size / thickness of

material. Second biggest : WRONG LOCATION. Rulebook says: 1/4 X 2

inches Steel - must completely encircle the driveshaft within 6 inches

of the front U-joint. Any 9.99 sec car must have a second loop at the rear.

No Matter what the ET a loop is required if your car has slicks.

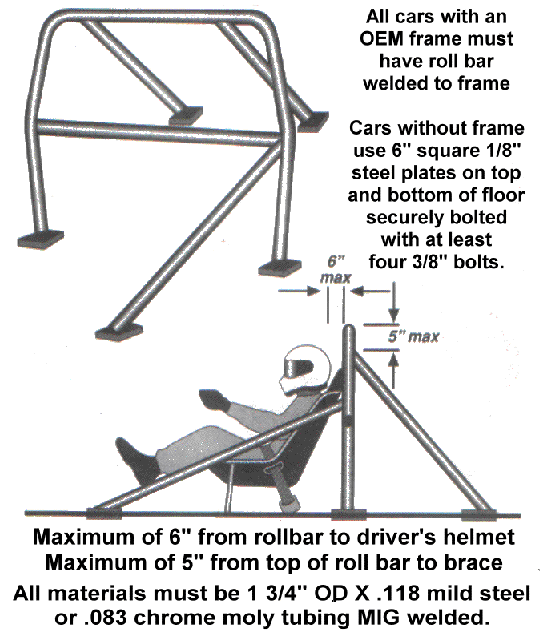

QUESTION: From our mailbox: What type of material do I need for a rollbar

and how is it attached to the car?

ANSWER: We have reprinted the complete IHRA rules on rollbar/cages

and have added the illustration below from the rulebook.

---------------------------------------------------

ROLL BARS{reprint from IHRA Rulebook}

Mandatory in all cars running 11.49 or quicker, or per class

requirements. All roll bars must be within 6 inches of the rear or

side of the driver's head, extend in height at least 3 inches above

the driver's helmet with driver in normal driving position, and be at

least as wide as the driver's shoulders or within 1 inch of the

driver's door. Rollbar must be adequately supported or cross-braced

to prevent forward or lateral collapse. Rear braces must be

of the same diameter and wall thickness as the roll bar and

intersect with the roll bar at a point not more than 5 inches from

the top of the roll bar. Sidebar must be included on driver's side

and must pass the driver at a point midway between the shoulder

and elbow. Swing-out sidebar permitted. All roll bars must have in

their construction a cross bar for seat bracing and as the shoulder-

harness attachment point; cross bar must be installed no more

than 4 inches below, and not above, the driver's shoulders or to

side bar. All vehicles with OEM frame (i.e. pickup truck where body

bolts to framerails) must have roll bar welded or bolted to frame.

Installation of frame connectors on unibody cars does not

constitute a frame; therefore, it is not necessary to have the roll bar

attached to the frame. Unibody cars with stock floor and firewall

(wheeltubs permitted) may attach roll bar with 6-inch x 6-inch x

.125-inch steel plates on top and bottom of floor bolted together

with at least four 3/8-inch bolts and nuts, or weld main hoop to

rocker sill area with .125-inch reinforcing plates, with plates welded

completely. All 4130 chrome moly tube welding must be done by

approved TIG heliarc process; mild steel welding must be done by

approved MIG wire feed or approved TIG heliarc process. Welding

must be free of slag and porosity. Any grinding of welds prohibited.

Roll bar must be padded anywhere driver's helmet

may contact it while in driving position. Adequate padding must

have minimum 1/4-inch compression or meet SFI Spec 45.1.

ROLL CAGE{reprint}

Mandatory in all cars running quicker than 10.99 seconds or faster

than 135 mph, or per class requirements. Cars with unaltered

firewall, floor and body (from firewall rearward, wheeltubs

permitted) running between 10.00 and 10.99, roll bar permitted in

place of roll cage, or per Class Requirements. Cars with altered

firewall, floor faster than 11.49 must have rollcage and window net.

All cage structures must be designed in an attempt to protect the

driver from any angle, 360 degrees. All 4130 chrome-moly tube

welding must be done by approved TIG heliarc process; mild steel

tube welding must be approved MIG wire feed or TIG heliarc

process. Welding must be free of slag and porosity. Any grinding of

welds prohibited. Additionally, roll cage must be padded anywhere

the driver's helmet may contact it while in the driving position.

With driver in driving position, helmet must be in front of main

hoop. If helmet is behind or under main hoop, additional tubing,

same size and thickness as roll cage, must be added to protect

driver. Main hoop may be laid back or forward, but driver must be

encapsulated within the required roll cage components. On

unibody cars with stock floor and firewall (wheel tubs permitted),

the roll cage may be bolted or welded to the floor/rocker box via 6-

inch x 6-inch x .125-inch steel plates

Unless attaching to OEM floor or frame, the minimum requirements for a

frame member to which a roll cage member is attached are 1 5/8-

inch x .118-inch MS or .083-inch CM round and/or 2-inch x 2-inch

x .058 MS or CM rectangular.

All cage structures must have in their construction a cross bar for

seat bracing and as the shoulder-harness attachment point; cross

bar must be installed no more than 4 inches below, and not above,

the driver's shoulders, or to side bar. All required rear braces must

be installed at a minimum angle of 30 degrees from vertical and

must be welded in. Side bar must pass the driver at a point midway

between the shoulder and elbow.

Unless an OEM framerail is located below and outside of driver's

legs, a rocker or sill bar, minimum 1 5/8-inch x .083 CM or .118 MS

or 2-inch x 2-inch x .058-inch CM or MS rectangular, is mandatory

in any car with a modified floor or rocker box within the roll-cage

uprights (excluding 6 square feet of transmission maintenance

opening). Rocker bar must be installed below and outside of

driver's legs and must tie into the main hoop, the forward hoop,

frame, frame extension, or side diagonal. Rocker bar may not tie

into swing-out side bar support. If rocker bar ties into side diagonal

more than 5 inches (edge to edge) from forward roll-cage support

or main hoop, a 1 5/8-inch x .083 CM or .118 MS brace/gusset is

mandatory between the diagonal and forward roll-cage support or

main hoop.

---------------------------------------------------

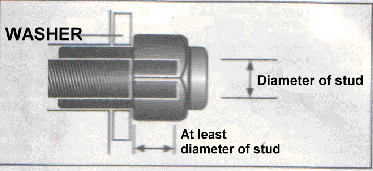

QUESTION: George H asked: What are the rules on wheel studs?

ANSWER: All wheel studs must project through the wheel both front

and rear when recessed aftermarket nuts are used. all wheel studs must project through lug nut when

stock nut is used. (illustration below)

---------------------------------------------------

QUESTION: L. B. wrote: I am considering putting a car

in the street class. What should I be made aware of before I go too

far? Is there anything special that has to be done to the car before I put it on the track? Am I allowed to remove any of the interior for weight reduction?

ANSWER: Other than the general rules posted on this page like

battery and driveshaft loop and neutral safety switch, etc., there are not

a lot of interior rules that apply to the street class. You may remove weight

from the interior so long as it does not compromise the safety of the vehicle or expose the drivers compartment to fumes from the engine or

trunk if a battery or fuel cell is located there. If the stock drivers seat and belts and mounts are not modified in any way you are OK as well.

---------------------------------------------------

QUESTION: Terry B asked: What are the rules on Fuel Systems

plumbing? Where do I run my lines? How do I mount my gas tank?

ANSWER: That's a lot of questions. Here we go with another reprint.

COMPLETE IHRA Fuel System rules {reprint}

Location: All fuel tanks, lines, pumps, valves, etc. must be

outside of the driver's compartment and within the confines of the frame

and/or steel body. Cool cans, fuel-distribution blocks, etc. must be located

at least 6 inches forward of the flywheel/bellhousing area on rear-wheel-

drive (RWD) cars, and on opposite side of flywheel/bellhousing area on

front-wheel-drive (FWD) cars. Fuel-pressure-gauge isolators, with steel-

braided line, may be mounted on firewall.

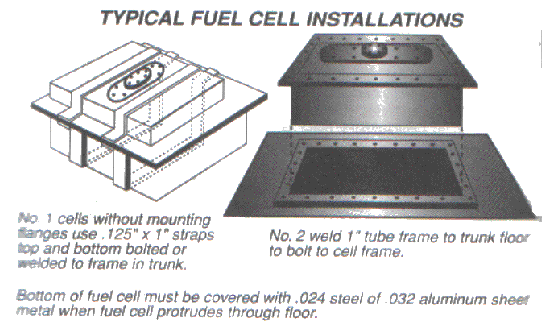

Tanks: When permitted by class regulations, fuel tanks located outside

body and/or frame must be enclosed in a steel tube frame constructed

of minimum 1 1/4-inch O.D. x .065 chrome moly or .118 mild-steel tubing.

All fuel tanks must be isolated from the driver's compartment by a firewall,

completely sealed to prevent any fuel from entering the driver's

compartment. All fuel tanks must have a pressure cap and be vented

outside of car body. A positive-locking screw on fuel-tank cap is

mandatory on all cars. Insulated fuel tanks prohibited. When used, fuel

cells must have a metal box protecting the part of the fuel cell that is

outside of body lines or trunk floor, excluding hose-connection area in

rear. Non-metallic fuel cells or tanks must be grounded to frame.

Lines: All non-OEM fuel lines (including gauge and/or data-recorder

lines) must be metallic, steel-braided or IHRA-accepted "woven or woven-

pushlock." A maximum of 12 inches total (front to rear) of non-metallic or

non-steel-braided hose is permitted for connection purposes only;

individual injector-nozzle fuel lines are excluded. Fuel lines (except steel-

braided lines) in the flywheel/bellhousing area must be enclosed in a 16-

inch length of steel tubing, 1/8-inch minimum wall thickness, securely

mounted as a protection against fuel-line rupture. Fuel lines may not be

routed in the driveshaft tunnel. IHRA-accepted woven or woven-pushlock

fuel lines: Aeroquip FC300, FC332; Aeroquip Star Lite 200; AQP; Earl's

Prolite; Gates LOL Plus; Goodridge 710; RussellTwist-Loc 836 and XRP

HS-79.

-------------------------------------------------

Question: John R. asked: Can I race my car without a hood?

Answer: We got asked this question a few times. Rulebook says:

FLASH SHIELDS

Carburetor/injector inlet must not be openly exposed. In lieu of

hood, carburetors/injectors must be equipped with a flash shield or

velocity stacks that cover the top, back, and sides, preventing fuel

from being siphoned into the airstream or blown into driver's face.

Additionally, any car that is driven, not towed, through the pits with

open stack(s) not protected by hood or scoop must have screening

installed on open stack(s) to prevent items from entering stack.

----------------------------------------------------

Question: Bruce J asked: I see people putting sandbags in their trunk

to help them get a little more traction. Is this legal?

Answer: Just throwing them in the trunk is not legal. Rulebook says:

As permitted in Class Requirements. Any material used for the purpose of

adding to a car's total weight must be permanently attached to the

car's structure and must not extend in front of or behind the rear of the

car's body or above the rear tires. No liquid or loose ballast permitted

(i.e. water, sandbags, rocks, shot bags, metal weights, etc.). Weight boxes

(2 maximum) made of 1/8-inch material may be constructed to hold small

items such as shot bags, lead bars, etc., as long as box and contents do

not weigh more than 100 pounds or as outlined in class requirements. The

box must be securely fastened to the frame or crossmember with at least

two 1/2-inch-diameter steel bolts. Any liquid other than engine fuel being

used, located behind the front firewall (on a front-engine car), is

considered ballast and is prohibited, except for intercooler tanks that contain water and/or ice only. Tank must be SFI spec 28.1 fuel cell of

maximum 3 gallons capacity. Must be securely mounted to frame, frame

member or OEM floorpan. Removable weight must be securely mounted

to the frame or frame structure by a minimum of two 1/2-inch-diameter

steel bolts per 100 pounds or one 3/8-inch bolt per 5 pounds. Hose

clamps, wire, strapping, tape, tie wraps, etc. for securing weight or ballast

prohibited. Maximum amount of removable and/or permanent ballast,

unless otherwise stated under Class Requirements, is 300pounds.

---------------------------------------------------

Roll bar / Rollcage RULES

We have contacted the IHRA Tech Director for a clarification

on the altered floor / firewall rule with regard to the ET where

this rule applies. He has informed us that if a floor or firewall

is altered in an 11.49 or quicker car it requires a rollcage - not

a 6 or 8 point rollbar. Upgrade kits are available for a reasonable

price from most chassis manufacturers so cost is not a concern.

**11.49 and quicker: IF YOU HAVE ALTERED YOUR FLOOR

OR FIREWALL - A FULL CAGE IS REQUIRED WITH WINDOW NET.

**Belt Date Codes apply to any vehicle quicker than 11.49

---------------------------------------------------

BATTERIES: The biggest problem

All batteries must be securely mounted. Batteries may not be

relocated into the driver or passenger compartments. Rear firewall

of .024-inch steel or .032-inch aluminum (including package tray)

required when battery is relocated in trunk. In lieu of rear firewall,

battery may be located in a sealed .024-inch-steel, .032-inch-aluminum,

or NHRA-accepted poly box. If sealed box is used in

lieu of rear firewall, box may not be used to secure battery and

must be vented outside of body. Relocated battery(s) must be

fastened to frame or frame structure with a minimum of two 3/8-

inch-diameter bolts. ("J" hooks prohibited or must have open end

welded shut.) Metal battery hold-down straps mandatory.

Strapping tape or Electrical zip ties prohibited. Stock unaltered battery

boxes / trays with OEM hold downs permitted only in stock location.

---------------------------------------------------

NEUTRAL SAFETY SWITCH

Most failures we have observed at Tech are here. Thankfully, it's usually

a pretty easy fix but a non - functioning neutral safety switch is a very

dangerous thing.

TRANSMISSION, Automatic {reprint}

Any non-OEM automatic floor-mounted automatic-transmission

shifter must be equipped with a spring-loaded positive reverse

lockout device to prevent the shifter from accidentally being put

into reverse gear. Functional neutral safety switch mandatory. All

transmission lines must be metallic or high-pressure-type hose. All

vehicles running quicker than 10.99 seconds or faster than 135

mph and using an automatic transmission must be equipped with a

transmission shield meeting SFI spec 4.1 and labeled accordingly.

(Blanket-type shield, appropriately labeled as meeting SFI spec

4.1, permitted.) All non-blanket-type shields must incorporate two

(or one, per manufacturer's instructions) 3/4" x 1/8" straps that bolt to

the shield on each side and pass under the transmission pan, or

transmission pan must be labeled as meeting SFI spec 4.1.

Permitted in all classes where an automatic transmission is used.

All vehicles running quicker than 9.99 seconds or faster than 135

mph and using an automatic transmission must be equipped with a

flexplate meeting SFI spec 29.1 and covered by a flexplate shield

meeting SFI spec 30.1.

PIT SPACE SAFETY

No work is to be done under a vehicle unless it is supported by Jack

stands. Either driver or crewman must be seated in the vehicle if it

is running [ setting timing, etc.] in the pit space. Any vehicle

with limited rearward visibility should have a crew member to guide

the driver out of his pit space. REMEMBER - Speed Limit is FIVE MPH in

the pits and on the return road once you pass the timeslip booth. Rulebook

says: It is mandatory that a driver be seated in the car in the normal driving

position anytime the engine is running, unless coupler or driveline is

removed from vehicle. The practice of transbrake testing, converter stalls,

line-loc testing, and/or transmission warming is prohibited in all classes,

in all areas of the event except in starting line approach areas beyond

staging, or unless vehicle is on jackstands. Non-compliance is grounds

for disqualification.{reprint}

FIRE EXTINGUISHERS

Fire Extinguishers are required in all Super / Pro entries and are

recommended in all cars. Don't be without one. If your car catches fire

at the far end of the track you're a minute or two away from the Track

Safety Truck - that could be too long. The Tech committee may soon

require ALL cars to have one - so be prepared.

COOLING SYSTEM{reprint}

All cooling systems/radiators must be installed in the stock location

for body style used. Cooling system must include an overflow:

minimum capacity 1 pint. Overflow tank/container must be securely

attached; no tie wraps, duct tape, etc.

BRAKES{reprint}

Brakes on each car, regardless of class, must be in good working

order with four-wheel hydraulic brakes as a minimum requirement.

Lightening of backing plates, brake drums, and/or brake shoes by

cutting or trimming metal prohibited. Cooling or lightening holes

may not be drilled in cast-iron disc-brake rotors. Brake lines must

be steel, steel-braided, or DOT-approved flexible and routed outside

the framerail, or enclosed in a 16-inch length of 1/8-inch-minimum-

wall-thickness steel tubing securely mounted where line(s) pass the

flywheel bellhousing area and not routed in the driveline tunnel. All

brake lines must be attached to chassis as per OEM style; hoses must

have mounting brackets; no tie wraps, tape, etc. All brake lines on any

rear-engine car must be protected inside of tubing or be of braided-steel

construction where they pass the engine. All pedals must be covered

with non-skid material. Automated and/or secondary braking systems

prohibited. Application and release of brakes must be a direct function of

the driver; electronics, pneumatics, or any other device may in no way

affect or assist brake operation. All line-locs (electric or hydraulic)

must be self-returning to normal brake operating mode.

RULE BOOK

C.B.D.R.A. Tech Inspectors use the IHRA rule book.

to inspect your vehicle on raceday. If you are building or buying a

Racecar get a rule book first. There's nothing worse than spending

a whole winter building a car and then failing TECH at the first race.

Safety Equipment requirements are determined by your ET - The faster

you go the more you need. [See below] For rule books try your local Speed shop

ALL CLASSES - Driveshaft loop MANDATORY with slicks - seat

belts - D.O.T. / SNELL Helmet - Neutral Safety switch

11.49 - SFI Scattershield for Standards - Fire Extinguisher - Rollbar

10.99 - Rollcage - SFI 4.1 Trans Shield - SFI 18-1 Harmonic Balancer

Aftermarket Axles - SFI 3.2A/1 Jacket

9.99 - SFI 29.1 Flexplate and SFI 30.1 Shield - Rear Driveshaft Loop

SFI 3.2A/5 Clothing and Neck Collar - Parachute [ over 150 MPH ]

8.99 - Chassis Certification Required by IHRA / NHRA

TECHNICAL INSPECTION WAIVER

Prior to competition (including private test sessions), all cars and

driver equipment must undergo a technical inspection, or have

been inspected under the Extended Technical Inspection program.

However, IHRA and its member tracks make no representations,

warranties or assurances that a technical inspection, including the

review of any written information will; 1) Detect every problem with

a car or a driver's personal equipment or clothing; 2) Detect every

problem with rule compliance, or; 3) Prevent injury, death or

property damage. The participant agrees that participant bears the

ultimate responsibility at all times to ensure the safety of

participant's vehicle and to ensure that participant complies with all

applicable IHRA rules. The participant agrees that participant is in

the best position to know about the construction and operation of

participant's vehicle, equipment and clothing, and whether there

has been compliance with all applicable IHRA rules.

-------------------------------------------------------